We had a nice intimate gathering this month, when one of our more ambitious members – Lupe Nielsen – presented an amazing pair of Sam Maloof inspired rocking chairs and matching side tables. Built in just 320 hours! More about her process, and tips and tricks later...

But first, we had our usual show and tell.

But first, we had our usual show and tell.

Pam brought a bark carving that she's been working on - her goal this summer is to put in 10 minutes a day with a carving knife. We were all envious of that dedication!

Mike brought a few examples of some lasered plywood pieces he's been working on. He’s been trying to perfect his technique, and asked for advice about keeping plywood flat in his laser engraver. (We all said– buy better plywood!)

These panels could potentially end up in a West Elm catalog, which would be very cool for him!

And Kate brought a few samples of her engraved journal covers,

she's been taking a CAD class and working with laser engraving.

That's some amazing work!

We were also sorry to hear that we were losing a few members - five in total are moving away. We’ll miss Ted’s expertise, Bill’s humor, Pete’s extraordinary cutting boards, Russ’s thoughtful questions, as well as words of wisdom from our former blog writer John, who is moving permanently to Arizona. It’s always a shame to have members move away, but we wish them well with their relocations. May your shops be cool and productive.

And finally - on to the main event. As always, Lupe’s presentation was detailed and filled with background information.

Lupe explained that although she's been doing woodworking for about five years, up until three years ago, she would not have had the necessary skills to build these pieces. These demanding chairs required a full range of woodworking expertise, including lathe work, coopering (as in barrel-making), carving, grinding, bandsaw work, bent lamination, sculpting, and more. Not for a rookie!

She did quite a bit of research first, reading several books including Maloof’s biography.

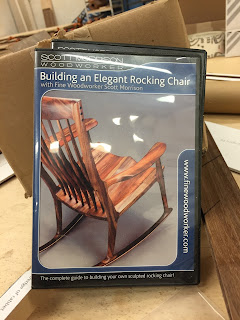

She thoroughly explored his thoughts about the evolution of this chair, and then researched the various plans that were available, including Charles Brock’s version, William Ng’s design, and eventually settled on Scott Morrison plan.

One reason was that his plan required only 8/4 lumber, which is much easier to acquire than the 12/4 lumber that is often required in other's plans. Oh, and did I mention that she decided to build a couple of matching tables too? I'm not sure where she gets her energy, but she has all of my respect.

She warned us that all plans include mistakes, and suggested that a thorough understanding of this chair is necessary before starting it.

Scott's chair design required these special router bits

to cut this mated joint.

And in addition to those, she bought or borrowed a Lie-Nielsen spoke shave and Auriou number nine rasp.

After all that shaping - (whew!) – she THEN used a die grinder and a Holy Galahad wheel on her Milwaukee grinder.

A particular challenge was the bent lamination of the rockers - she built a one-part jig and laminated a rocker, but was unhappy with it. It needed even pressure for a better glue-up, so she ended up making a two part jig that allowed her to apply better pressure for a stronger lamination.

These Klingspor memory blocks helped her with the final sanding on all the sculpted parts.

If you know anything about Lupe, you know she is a stickler for a good finish on her pieces. For first coat was Tried and True Danish oil.

This was then followed by Maloof's own poly/oil finish. She started with 180 grit wet sanding, and by the time the last coat was applied, she was up to 1500 grit paper. Whew! I think she applied six or seven coats, before the final wax.

Why do we always pointed out the flaws in our pieces?

Lupe explained that she had a few areas that required some TLC. She ended up using a slow curing tinted epoxy to fix a few defects, and some Mohawk stain markers for touching up the epoxied areas.

Honestly – you had to put on your readers to see any of her mistakes!

Lupe explained that she had a few areas that required some TLC. She ended up using a slow curing tinted epoxy to fix a few defects, and some Mohawk stain markers for touching up the epoxied areas.

Honestly – you had to put on your readers to see any of her mistakes!

The evening wrapped up with everyone trying out her chairs. We could be more amazed at the work she does, nor more pleased with her efforts. Great work, Lupe!

It was a delight to see everyone's smiling faces at the Sin City Woodworker's meeting over a week ago. I would like to add a few little points which were not mentioned in the above report:

ReplyDelete- Overall shaping and sanding is achieved by going from the coarser tools to the finer ones, in this order: Table saw and band saw shaping, holey galahad grinder wheels down to regular 24 and 36 grit grinder wheels, rasps, spokeshaves, Festool rotary sander, hand sanding. The process is long and tedious. Once one reaches the sanding stage, sandpaper goes from 40, 80, 120, 150, 180 to 220.

- Glues used: The chairs were put together with Dark Titebond glue. Slow curing epoxy was used to attach the spindles to the chair, as they are difficult to clamp and keep under the pressure that Titebond requires.

- Errors were few and minor. To correct a 1/4" long router blow out on one of the joints, I used Mohawk epoxy putty, and covered it up with one of their marker stains. You have to leave the stain overnight for it to adhere completely to that putty. It was such a good repair that it is nearly invisible.

- Finishing: Once the chairs are finished to the final sanding grit of 220, the coats are as follows:

1 - Coat of Tried and True Danish Oil

2 - Coat of Maloof Oil / Urethane finish. Wet sanded with 220 sandpaper.

3 - Coat of Maloof Oil / Urethane finish. Wet sanded with 320 sandpaper.

4 - Coat of Maloof Oil / Urethane finish. Wet sanded with 400 sandpaper.

5 - Coat of Maloof Oil / Wax finish. Wet sanded with 600 sandpaper.

6 - Coat of Maloof Oil / Wax finish. Wet sanded with 1500 sandpaper.

7 - Coat of Maloof Oil / Wax finish. Wet sanded with 1500 sandpaper again.

The oil should be rubbed dry after each application with a clean cotton rag.

Each of those coats is applied after the chair is allowed to dry for 24 hours. It takes a week to have the final finish.

Safety note: Please dispose of all the rags and oil materials in a separate container full of water or dedicated can, away from your property. They are extremely flammable. My dedicated container spontaneously combusted three times during this process. Thankfully, it is a dedicated metal lidded garbage can at least 10 yards away from the building.

Fast forward to today - Friday, June 24, 2016... The chairs and tables are completely dry. After examining them, there are a few tiny rough spots with dried oil on them, which might not have been rubbed off during the process. I will be taking a little 0000 steel wool with Oil/Wax finish, to wet sand those little rough spots, and wipe them off with a clean rag.

And those are my final notes!

It was an excellent exercise in testing and teaching me new woodworking skills. I am glad I made these pieces.

Sincerely, Lupe Nielsen

Download Your 150 Free Woodworking Plans

ReplyDeletehttp://bit.ly/150Woodworkingplans