Well, I think it goes without saying that our end of the year Christmas Party and the culmination of Jamie's 2 x 4 x 8 Challenge was a huge success. There were over 40 members and guests in attendance and I must admit I was slack in my counting -- probably closer to 50+ people there! For starters, we had some great, freebie door prizes in the form of these tape measures. Steve M. donated the labels for them so Sin City Woodworkers group now has our own, private label tape measures. There they are, hope you were able to get your own in your favorite color.

The festivities started as many of our meetings do, people catching up with whatever happened during the month and just talking and sharing some good times together. There were three, huge differences though --- Food, Wine, and Sangria! Thanks to all who either brought in the goodies for us to share and also to those who set it all up. We had quite a spread which really added to the festive mood of the night. There were fourteen entries in the challenge which were placed around the room on tables. Each entry had a numbered tag on it to identify the project. Great selection of pieces and I think the quality of the projects indicate the talents we have in our group. After about an hour, Jamie announced that it was time for the voting to begin. This was done on the honor system with a clip board showing the numbers of the projects. We all put one tally mark next to the number of the project of our choice …………… and the winner is:

|

| Pete, his table and gift certificate -- Congrats!! |

Pete Hauser with his beautiful table. He decided to use a construction grade piece of Redwood. He won a $100.00 gift card from Lee Valley.

|

| Mike Cook, Second Place Carving --- Congrats!! |

Mike Cook came in second place after the votes were tallied. He created this beautiful carving and used Redwood too. The small easel on the table was made and carved from the remnants of his 2 x 4.

|

| John Eugster, Third Place Stool -- Congrats !! |

The project that came in third place was my stool. This was made from a 2x4 of Douglas Fir. The top was woven from Hong Kong Seagrass and the mortise and tenon joints are pegged with Chakte Kok dowels.

All of the work was so nicely done that everyone wanted to get a bit of the "back story" on their creation.

|

| Nutcracker: 2x4 was resawn into thirds, features movable jaw, lighted eyes, and dowel arms. |

|

Ned's hand cut Dovetailed box featuring a wooden hinge.

|

|

| Ken with his dog bed, notice the dog bone posts! |

|

| Jim's Lantern, he used Vellum as a substitute for traditional rice paper |

|

| Jamie made these during a "hungry moment" The platter was laminated, force dried, and turned within 2 hours! |

|

| Neal's' candle holders with a Christmas/winter motif |

|

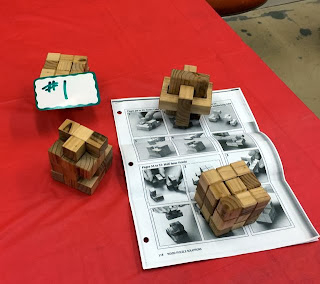

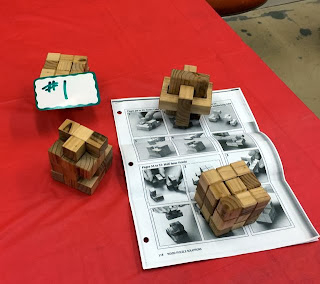

| Set of puzzle blocks made by Ed |

|

| Lupe's wooden gourmet kitchen assortment |

Lupe, being the overachiever that she is, also made a second project which Norm created the decals for. The

dead flat black flocking generated a lot of interest so here is a

LINK to her supplier.

|

| Magical! |

|

| Richard's Wine Presentation Box |

This wine presentation box that features finger joints and a sliding lid brought quite a few positive comments from Jamie who coerced him, eh I mean

suggested that it should be added to the raffle table. Being a good sport Richard added it to the already full table of donated items.

|

| Donated Items for the Raffle which brought about $150.00 to the club. |

Seems like whenever we have a raffle during one of our meetings one person is the lucky one and their tickets get drawn several times. Russ was the "chosen one" that night and not only did he win the wine box, his numbers were called several times. With a nod to the season, he re-donated items so that others of us had an opportunity to take home something. His attitude was contagious and several others followed suit. Makes our group great doesn't it?

|

| Happy New Year |

The formal meeting ended with our members drawings for Lee Valley gift cards. Kris Hagon received a $25.00 one and Richard Daugherty, Ted Warren, and me lucked out with a $50.00. Do I look happy? you bet! Great way to start 2014 with a purchase of something special from Lee Valley.

This ended the formal part of the party and people started to filter out. I was among those so I have no idea how long others may have stayed but there was plenty of food and libations to keep you there for quite some time! Thanks to all of you that attended, brought food, and created a project for the challenge. Sounds as if some are already planning what to do for next year so my guess is that this will become a tradition with the club.

Last but not least; as always Lupe does a great job of taking photographs and videos at our meetings. We've tried several different ways to get them from her camera, to my computer, and then on to the blog. I usually edit them to illustrate the content of the blog. Since there were so many interesting, random shots taken throughout the party here's is a link to the "contact sheet" of all the pictures. I'm pretty sure you'll be able to view it via this

LINK. I won't guarantee it though, you may need to have a Dropbox account which is how we share the files now.

Merry Christmas to You and Yours,

Have a Happy New Year

Well, I think it goes without saying that our end of the year Christmas Party and the culmination of Jamie's 2 x 4 x 8 Challenge was a huge success. There were over 40 members and guests in attendance and I must admit I was slack in my counting -- probably closer to 50+ people there! For starters, we had some great, freebie door prizes in the form of these tape measures. Steve M. donated the labels for them so Sin City Woodworkers group now has our own, private label tape measures. There they are, hope you were able to get your own in your favorite color.

Well, I think it goes without saying that our end of the year Christmas Party and the culmination of Jamie's 2 x 4 x 8 Challenge was a huge success. There were over 40 members and guests in attendance and I must admit I was slack in my counting -- probably closer to 50+ people there! For starters, we had some great, freebie door prizes in the form of these tape measures. Steve M. donated the labels for them so Sin City Woodworkers group now has our own, private label tape measures. There they are, hope you were able to get your own in your favorite color.